2001

"The Honeymoon Cottage"

"The Honeymoon Cottage"

Build a Split-Rail Fence in Impossible Soil

by Dorothy Ainsworth

A piece of property in the country is just a romantic notion with a mortgage attached...until you put some sweat equity into it. Then, if you're a do-it-yourselfer like me, the improvements are so gratifying, it can become your passion.

The quickest and most visual way to transform plain old land to the status of homestead, farm, or ranch is to put a handsome fence around it. It's like outlining a chapter before you write the book. And because we're territorial animals, fences define our boundaries and make us feel secure.

Some people like white picket fences, some prefer post and wire, but most of us backwoodsy types love natural wood when we can afford it.

A split-rail fence, whether straight or zigzagged, is inherently rural in its meandering style and retains a poetic beauty even after it's old and gray.

View from the road

View from the road

I had always wanted to build one, so when my neighbor offered to sell me 82 hand-split cedar rails (10-footers) for $4 apiece (half-price), it was a deal I couldn't pass up. While visualizing the finished fence in all its rustic splendor, I bought them on the spot. Then reality hit, and I wondered how in the heck I was going to anchor my dream fence into nightmare soil.

The hard rocky ground along the front of my property was virtually impenetrable by conventional digging, so I immediately thought of rebar posts.

Rebar has been a quick, cheap, and strong solution to a lot of my problems over the past 20 years of property development. I had fastened my log and timber house together with rebar, built a retaining wall with railroad ties and rebar, staked out trees with rebar, and, of course, used rebar in all my concrete work.

Close up

Close up

Rebar is as versatile to this lady pink-neck as Jeff Foxworthy says bailing wire and duct tape are to a bonafide redneck.

I came up with a workable idea, but it involved some help. I'd ask my boyfriend Kirt to pound several pairs of rebar posts into the ground with a sledgehammer. The legs of each pair 6" would be apart. Then I'd wire the posts together top and bottom to keep them parallel and use the bottom wire, set 6" off the ground, to rest the first rail on.

I would need 48 5-foot lengths of 3/4" rebar (24-pair), set at 8-foot centers, for a 184-foot fence. That length would use all my rails. With gut-busting effort and some real luck, I figured they'd go into the ground 18 inches, leaving about 3 feet for the fence height.

Like so many projects before, high energy expenditure had to compensate for low money expenditure ($12,000/yr. income). My cost for this fence would be 1/10th the going rate. There's an old saying: "You can augment your means or diminish your wants." Since I'm not willing to do either, I spend myself (a rechargeable resource) and try to have it all!

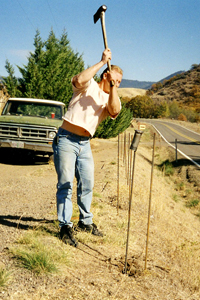

Dorothy breaks through the gravel

Dorothy breaks through the gravel

The local steel supplier had 3/4" rebar in stock for 30 cents per foot and cut it to length for me free. I recruited Kirt and we started in, using a small-diameter post-pounder-cylinder (homemade) and a big sledge. With sheer power and brute force and all the accompanying sounds, Kirt "Jackhammer" Meyer drove the rebar in like a madman on the "Gong Show." As we moved along the staked-out line, I stabilized each post with a coward's grip and wincing face, while dodging the near misses with every blow and making a few of my own sound effects.

Kirt pounds the rebar home

Kirt pounds the rebar home

Eyeballing the angle of attack

Eyeballing the angle of attack

Plumbing the rebar "post"

Plumbing the rebar "post"

If I hadn't had Kirt on hand, I would have ground a pencil point on one end of each rebar post to help it penetrate the ground. I've found that grinding metal on an electric grinding wheel is surprisingly fast and easy, and it's fun to watch the sparks fly! Also, because I'm short, I would have stood on a step ladder for better striking power with the sledge. There's almost always a way to work alone, but the task takes longer.

When Kirt's job was done, so was he - understandably. As he staggered off to take a well-earned rest, I proceeded on with the fun part.

For wire, I had chosen solid 10-gauge copper because of its warm color, ease in bending, and no-rust properties. I bought a 200-foot roll at 10 cents per foot (2001).

I twisted all the bottom wires around and between the posts, satisfied that the rough-textured rebar gripped the wire securely. Then I laid on the courses of split-rails, alternating 4, then 3, then 4, on down the line for a pleasing design.

I placed the final wire 4" down from the top so the last rail would cap off the fence, hiding the wire and the post-ends. Any rebar sticking its head up too far was decapitated with a Sawzall.

View from driveway

View from driveway

Fence in between dirt road and highway

Fence in between dirt road and highway

I splashed some stain on the rails, and the fence was completed in one day, for a grand total of $2.50/L.ft. That was six years ago and it hasn't aged a bit. I wish I could say the same!

Summer

Summer

Winter

Winter